| DESIGN BASIS | GB | API |

| DESIGN CRITERIA | GB/T 12235 | BS1868 |

| STRUCTURE LENGTH | GB/T 12221 | ASMEB16.10 |

| CONNECTING FLANGE | JB/T 79-94 | ASMEB16.5 |

| TEST AND INSPECTION | JB/T9092 | AP11598 |

MATERIAL LIST OF MAIN ACCESSORIES:

| PART NAME | MATERIAL | |

| STAINLESS STEEL | CAST STEEL | |

| BODY | CF8 | WCB |

| VALVE DISC | CF8 | 2Cr13 |

| SHIM | PTFE | 304+GRAPHITE |

| SEAT | CF8 | 2Cr13 |

| CAP | CF8 | WCB |

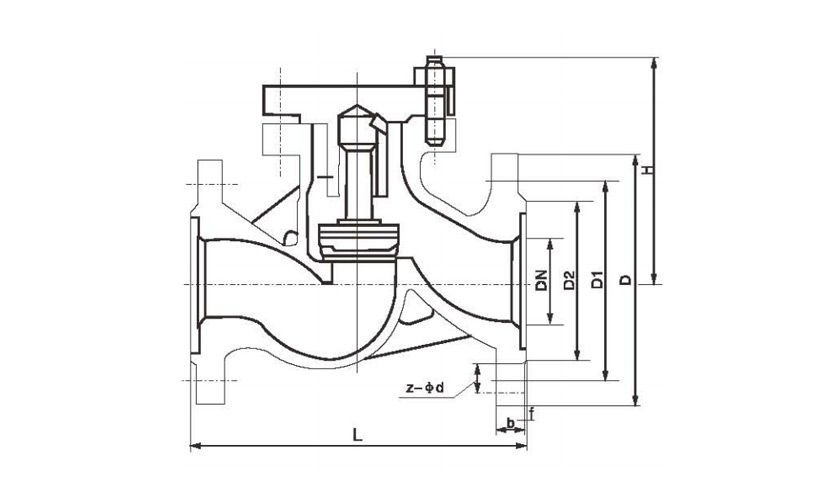

MAIN SIZE:

| PN | DN | L | D | D1 | D2 | b | Z-φd | H |

| 1.6Mpa | 15 | 130 | 95 | 65 | 45 | 14 | 4-14 | 77 |

| 20 | 150 | 105 | 75 | 55 | 14 | 4-14 | 77 | |

| 25 | 160 | 115 | 85 | 65 | 14 | 4-14 | 80 | |

| 32 | 180 | 135 | 100 | 78 | 16 | 4-18 | 85 | |

| 40 | 200 | 145 | 110 | 85 | 16 | 4-18 | 95 | |

| 50 | 230 | 160 | 125 | 100 | 16 | 4-18 | 105 | |

| 65 | 290 | 180 | 145 | 120 | 18 | 4-18 | 120 | |

| 80 | 310 | 195 | 160 | 135 | 20 | 8-18 | 130 | |

| 100 | 350 | 215 | 180 | 155 | 20 | 8-18 | 140 | |

| 125 | 400 | 245 | 210 | 185 | 22 | 8-18 | 155 | |

| 150 | 480 | 280 | 240 | 210 | 24 | 8-23 | 180 | |

| 200 | 600 | 335 | 295 | 265 | 26 | 12-23 | 215 | |

| 250 | 730 | 405 | 355 | 320 | 30 | 12-25 | 260 | |

| 300 | 850 | 460 | 410 | 375 | 34 | 12-25 | 315 |

Product description:

Working principle: the check valve automatically opens and closes the valve disc depending on the flow of medium itself to prevent medium backflow.

Storage, maintenance, installation and use:

1. The valve shall be stored in a dry and ventilated room, and both ends of the valve channel shall be blocked.

2. Valves stored for a long time shall be inspected regularly to remove dirt. Pay special attention to the cleaning of the sealing surface to prevent damage to the sealing surface.

3. Before installation, carefully check whether the valve mark is consistent with the use requirements.

4. Check the inner cavity and sealing surface of the valve before installation. If there is dirt, wipe it with a cleaning cloth.

5. Before installation, the flow direction mark on the valve shall be consistent with the medium flow direction.

6. The lifting vertical disc check valve shall be installed on the vertical pipeline, and the lifting horizontal disc check valve and swing check valve shall be installed on the horizontal pipeline.

7. Pay attention to whether the valve has abnormal sound and vibration during use. In order to prevent water hammer effect in the pipeline, pay attention to the pressure fluctuation of pipeline medium.

K WOD Valve, SJFM brand, WOD brand, WOD Valve, unique and advanced design concept of the product, combined with high-end and exquisite CNC processing technology, the processing size of each valve is strictly controlled within the tolerance range, and the processing size of all structural design and accessories selection is strictly in accordance with the industry front-end standards and 6S, CE, TS, ISO9001, ISO14000, ISO18000, API, GB and other standards. Make each valve practical, safe and long-life, and bring high utilization value to customers.

浙公网安备 33039902000220号

浙公网安备 33039902000220号