| NOMINAL DIAMETER | DN8-DN100、1/2"-4" |

| NOMINAL PRESSURE | PN1.6 MPA (200WOG) |

| SHELL STRENGTH TEST PRESSURE | PN2.4 MPA |

| LOW PRESSURE AIR TIGHTNESS TEST PRESSURE | 0.8MPA |

| APPLICABLE MEDIA | WATER、OIL、GAS、NITRIC ACID、ACETIC ACID |

| DESIGN AND MANUFACTURING STANDARDS | ANSI B16.34、GB/T-12224-2015 |

| TEST STANDARD | API598、GB/T13927-2008、EN12516-3 |

| THREAD STANDARD | G、BSP、BSPT、DIN259 、DIN2999、ISO228 、NPT 、PT 、ISO7/1 |

MATERIAL LIST OF MAIN ACCESSORIES:

| VALVE BODY | A216(WCB)、A351 CF8、CF8M、CF3M、321、2205 |

| VALVE COVER | A216(WCB)、A351 CF8、CF8M、CF3M、321、2205 |

| FILTER SCREEN | SUS304、SUS316 |

| FILLER | PTFE、RPTFE、M111、M1600、M1700、PPL |

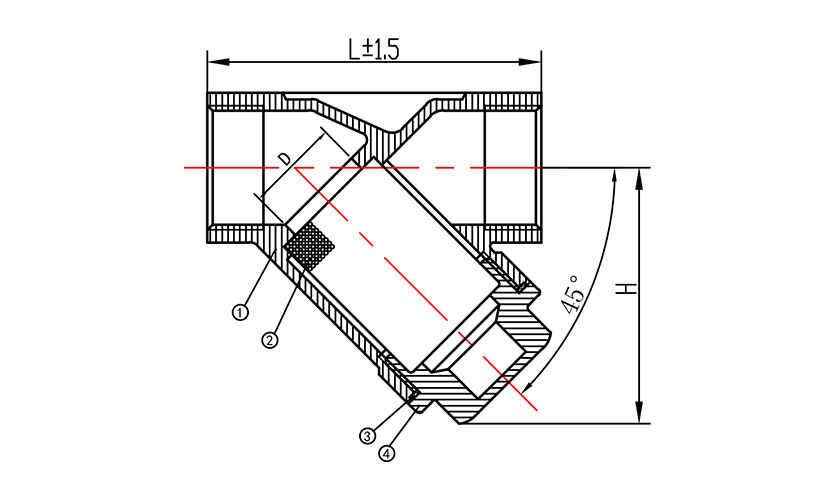

| NO. | PART NAME | MATERIAL | QTY |

| 1 | BODY | CF8/CF8M | 1 |

| 2 | FILTER | S304/S316 | 1 |

| 3 | JOINT GASKET | PTFE/RPTFE | 1 |

| 4 | CAP | CF8/CF8M | 1 |

MAIN SIZE:

| SIZE | 1/4" | 3/8" | 1/2" | 3/4" | 1" | 1¼" |

| DN | 8 | 10 | 15 | 20 | 25 | 32 |

| D | 8 | 10 | 15 | 20 | 25 | 32 |

| L±1.5 | 54 | 54 | 59 | 73 | 84 | 97 |

| H | 35 | 35 | 45 | 60 | 63 | 80 |

| (Kg) | 0.135 | 0.120 | 0.155 | 0.275 | 0.355 | 0.55 |

| SIZE | 1½" | 2" | 2½" | 3" | 4" |

| DN | 40 | 50 | 65 | 80 | 100 |

| D | 40 | 50 | 65 | 80 | 100 |

| L±1.5 | 106 | 127 | 165 | 188 | 232 |

| H | 88 | 109 | 138 | 153 | 196 |

| (Kg) | 0.73 | 1.235 | 2.43 | 3.835 | 5.835 |

Product description:

Y-type filter is an indispensable filtering device for the pipeline system conveying medium. Y-type filter is usually installed at the inlet of pressure reducing valve, pressure relief valve, constant water level valve or other equipment to remove impurities in the medium and protect the normal use of valves and equipment. Y-type filter has the characteristics of advanced structure, low resistance and convenient sewage discharge.

The filtering accuracy is 18 mesh to 480 mesh.

3、 Installation and maintenance

1. Use the filter reasonably according to the application range of the filter.

2. Before installation, the welding slag and sundries in the pipeline shall be removed to avoid damaging the filter. 3. The installation shall be carried out in the direction of the arrow of the filter.

4. After the initial operation of the filter operation and maintenance system for a period of time (generally no more than one week), it shall be cleaned to remove the impurities and dirt accumulated on the filter screen during the initial operation of the system. After that, it must be cleaned regularly. The cleaning times depend on the working conditions. If the filter does not have a drain plug, remove the filter screen stopper and filter screen when cleaning the filter. Warning: before each maintenance and cleaning, the filter shall be isolated from the pressurized system. After cleaning, use a new gasket for reinstallation.

5. When the filter is in use, it shall be regularly checked whether it works normally. If any abnormality is found, it shall be eliminated immediately to avoid accidents.

6. In case of long-term storage, it shall be placed in a ventilated and dry place, and shall be inspected and maintained regularly.

K WOD Valve, SJFM brand and WOD brand, with unique and advanced design concept, combined with high-end and exquisite CNC processing technology, the processing size of each valve is strictly controlled within the tolerance range, and the processing size of all structural design and accessories selection is strictly in accordance with the industry front-end standards and 6S, CE, TS, ISO9001, ISO14000, ISO18000, API, GB and other standards. Make each valve practical, safe and long-life, and bring high utilization value to customers.

浙公网安备 33039902000220号

浙公网安备 33039902000220号