| NOMINAL DIAMETER | DN8-DN100、3/8"-4" |

| NOMINAL PRESSURE | PN1.6、2.5、4.0、6.4 MPA (1000WOG) |

| SHELL STRENGTH TEST PRESSURE | PN2.4 、3.8 、6.0 、9.6 MPA |

| LOW PRESSURE AIR TIGHTNESS TEST PRESSURE | 0.8MPA |

| APPLICABLE MEDIA | WATER、OIL、GAS、NITRIC ACID、ACETIC ACID |

| DESIGN AND MANUFACTURING STANDARDS | ANSI B16.34、GB/T-12224-2015 |

| TEST STANDARD | API598、GB/T13927-2008、EN12516-3 |

| THREAD STANDARD | G、BSP、BSPT、DIN259 、DIN2999、ISO228 、NPT 、PT 、ISO7/1 |

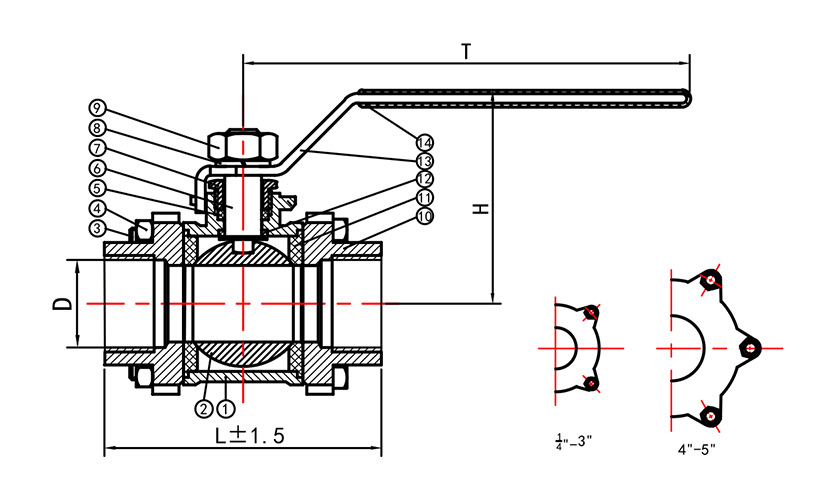

MATERIAL LIST OF MAIN ACCESSORIES:

| VALVE BODY | A216(WCB)、A351 CF8、CF8M、CF3M、321、2205 |

| VALVE COVER | A216(WCB)、A351 CF8、CF8M、CF3M、321、2205 |

| SPHERE | SUS304、SUS316 、SUS316L、SUS321、SUS2205 |

| VALVE STEM | SUS304、SUS316 、SUS316L、SUS321、SUS2205 |

| VALVE SEAT | PTFE、RPTFE、M111、M1600、M1700、PPL 、PCTFE、PEEK |

| FILLER | PTFE、RPTFE、M111、M1600、M1700、PPL |

| NO. | PART NAME | MATERIAL | QTY |

| 1 | BODY | WCB/CF8/CF8M | 1 |

| 2 | BALL | S304/S316 | 1 |

| 3 | BOLT | S201/S304 | 4~6 |

| 4 | NUT | S201/S304 | 4~12 |

| 5 | PACKING | PTFE/RPTFE | 1 |

| 6 | STEM | S304/S316 | 1 |

| 7 | GLAND | S201/S304 | 1 |

| 8 | SPRING WASHER | S201/S304 | 1 |

| 9 | NUT | S201/S304 | 1 |

| 10 | CAP | WCB/CF8/CF8M | 2 |

| 11 | SEAT | PTFE/RPTFE | 2 |

| 12 | THRUST WASHER | PTFE/RPTFE | 1 |

| 13 | HANDLE | S201/S304 | 1 |

| 14 | HANDLE COVER | PVC | 1 |

| 15 | LOCK | S201/S304 |

MAIN SIZE:

| SIZE | 1/4" | 3/8" | 1/2" | 3/4" | 1" | 1¼" |

| DN | 8 | 10 | 15 | 20 | 25 | 32 |

| D | 8 | 10 | 15 | 20 | 25 | 32 |

| L±1.5 | 66 | 66 | 63 | 70 | 82 | 99 |

| H | 51 | 51 | 56 | 64 | 69 | 80 |

| T | 89 | 89 | 107 | 120 | 126 | 143 |

| KG | 0.36 | 0.333 | 0.42 | 0.615 | 0.835 | 1.255 |

| SIZE | 1½" | 2" | 2½" | 3" | 4" |

| DN | 40 | 50 | 65 | 80 | 100 |

| D | 40 | 50 | 65 | 80 | 100 |

| L±1.5 | 109 | 126 | 185 | 205 | 235 |

| H | 89 | 101 | 121 | 141 | 169 |

| T | 160 | 171 | 205 | 235 | 296 |

| KG | 1.725 | 2.43 | 4.915 | 7.49 | 13.515 |

Product description:

The structure of the ball valve: it is assembled by the valve body, the valve cover and the ball core. The ball core is connected by the valve stem, and the shaft can be rotated 90 degrees to realize the opening and closing function. It is mainly used for pipeline switch and emergency cut-off. It can also design ball core V-shaped opening to achieve flow regulation function.

Structural features:

A light torque: the elastic valve seat is in elastic contact with the ball core, and the sealing specific pressure is controllable, which provides elastic avoidance for the ball when rotating. The operating torque is uniform without jamming, the hand feels lubricated, and there is no locking when opening. The valve seat shall be chamfered to avoid that the ball mouth will not be embedded into the valve seat under the condition of high pressure difference.

B the valve seat has strong sealing performance. The pre-sealed of the elastic valve seat forms an effective self sealing effect under the pressure of the medium after the valve is closed.

C. the valve seat has long service life, long pre-compression stroke of elastic valve seat and large amount of wear compensation. At the same time, it has the form of upstream seal and downstream support, so that it can be sealed from the beginning of closing to the stroke before sealing without medium pressure. Only when the seal is formed at the moment of closing, the pressure on the sealing surface of the valve seat will rise, so as to achieve sealing durability.

D. valve seat trimming and wrapping cold flow limiting structure: valve seat trimming effectively uses the unsupported area of the ball and valve seat, and the valve seat lining ring is wrapped to prevent cold flow collapse, so as to realize high pressure bearing.

E. the lower convex design of the valve stem can prevent flying out and prevent valve stem leakage

F anti static design ensures that the current between the ball core valve rod and the valve body is directed outward, effectively avoiding safety accidents caused by static electricity.

G the O-ring on the valve stem has a good self sealing effect and plays an effective and sealing role in the medium in the valve cavity.

H valve rod packing V-shaped design, and the plane seal of rod valve packing compression ring is precision machined and assembled to achieve no leakage effect.

I disc spring compensation design to adapt to the automatic elastic compensation effect in case of seal packing ring wear, so as to reduce leakage.

J full flow design ensures the rapid flow of medium in the valve, so as to save time, high efficiency and other characteristics.

K WOD Valve, SJFM brand and WOD brand, with unique and advanced design concept, combined with high-end and exquisite CNC processing technology, the processing size of each valve is strictly controlled within the tolerance range, and the processing size of all structural design and accessories selection is strictly in accordance with the industry front-end standards and 6S, CE, TS, ISO9001, ISO14000, ISO18000, API, GB and other standards. Make each valve practical, safe and long-life, and bring high utilization value to customers.

浙公网安备 33039902000220号

浙公网安备 33039902000220号